AGGREGATES TREATMENT EQUIPMENT

Horizontal Screens

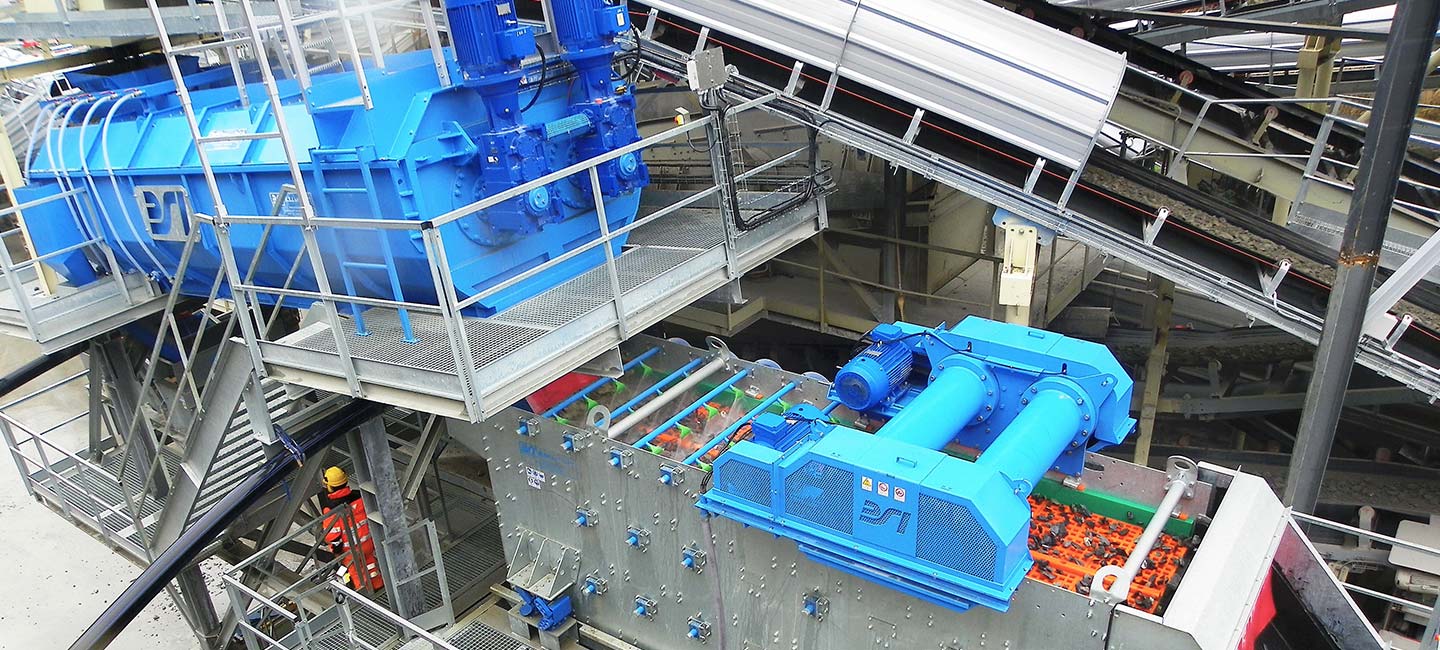

VHS Series

Characterized by a wide range of use and a high efficiency, the ease of use and the reduced maintenance required, make this the perfect device to use in aggregate screening operations.

Gallery

Main construction specifications

- Vibrating structure

heavy duty and with great rigidity. All components are joined together by bolts (no welding, to avoid any chance of cracks).

- Vibrating assembly

made by TWO vibration units, each with eccentric masses, separately tunable to obtain the correct stroke and incline. Lubricated by oil bath, the two unist rotates over special obscillating roller bearings, specifically designed for vibrating devices.

- Eccentric Masses

fine tunable eccentricity, to adapt the vibration amplitude to the gradation of feeding material, generating elliptical or linear vibration actions.

- Support system

harmonic Iron spring coils or elastomer mount swing bars, depending on the applications and the dimension of the device.

- Screening decks

equipped with steel clothes / perforated metal sheets / Rubber lined Sheets / urethane panels. The large room between the screen decks facilitates the access to the screening media, and allow an easyer maintenance.

- Lubrication

grease or oil bath, depending on the application and the screen dimension.

- Electric motors

directly assembled on the Vibrating assembly.

- Vibration parameters tuning:

stroke and incline degree of vibration are both separately tunable, by changing the eccentric masses position and the mutual positon of the two shafts of the vibration mechanism. The frequency is variable by the means of a frequency controlled electric drive.

Thecnical Specifications

| Screening decks width | [ mm ] | 1500 - 2100 | |

| Screening decks length | [ mm ] | 4000 - 6000 | |

| Number of screening decks | 2 - 4 | ||

| Total Installed Power | [ kW ] | 18.4 - 37 | |

| Approx. Weight | [ kg ] | 3300 – 10600 |

Optional

- Washing plant applied on all screening decks. It consists of two distribution tubes (collectors) and a series of washing pipes, connected to the collector by rubber hoses. Each washing pipe is equipped with a series of special nozzles and a control gate valve to allow a differentiated dosage of water on the various area of the screen.

- Dust top seal available

- full deep hot galvanization of all components (but the mechanicla machined ones)

- Speed control via frequency driver