AGGREGATES TREATMENT EQUIPMENT

Secondary Impact Crushers

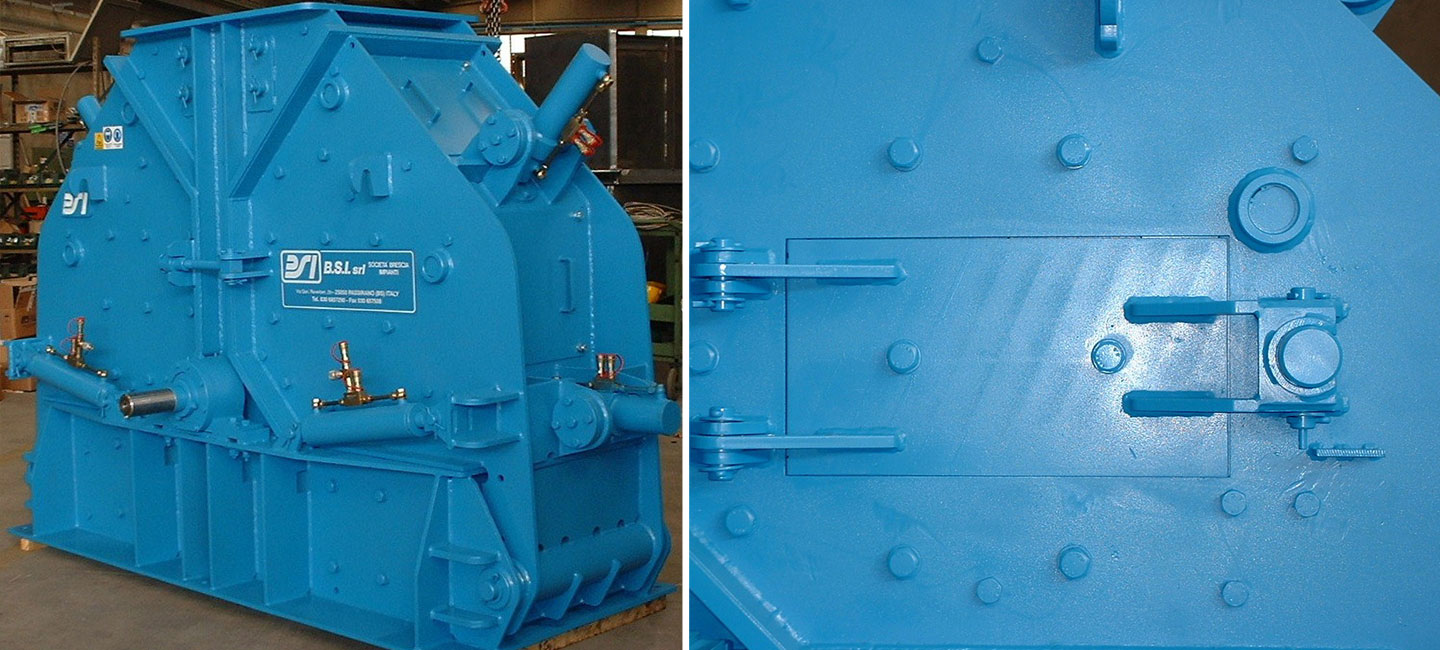

PGC Series

Secondary impact reversible crushers Series PGC, characterized by a wide range of applications, are particularly suitable for the crushing of aggregates of various types for the production of sands and fine gravels with low content of filler and a compact output gradation.

The ease of Use and the reduced maintenance make it the ideal machines to crush gravel and stones

Gallery

Main construction specifications

- Bi-directional rotation

the rotor of this crusher is capable in turning both directions, consequently working times are doubled into the respect of a machine with a single direction of rotation.

- Frame and mobile impact surfaces

designed for heavy-duty service, made thick welded metal sheet. They have been calcualted to withstand over-stress in the event of breakage of impact hammers.

- Shaft

built heavy-duty service, in high fatigue-resistant steel, supported by oscillating roller bearings widely oversized, which guarantee maximum reliability even in the most demanding applications.

- Rotor

heavy duty construction, made of steel in several sectors, independent of each other, set in phase and fixed each to the shaft by means of binders.

- Shaft supports

for heavy-duty service, equipped with grease labyrinth selas for bearing protection.

- Hydraulic opening of crusher structure

by the action of hydraulic cylinders feeded through opening speed regulation valves and equipped with a safety valves to prevent accidental closure of the shells during maintenance operations.

- Reversible impact bars (hammers)

for heavy-duty service, slided into the rotor without any locking (to avoid blockage for maintenance). They are made of chrome alloy with a hardness of 62-65 HRC (standard) or Higher depending on the usage and the specific application.

- Impact side armor

for heavy-duty service, in chrome alloy with hardness 56-62 HRC (standard). Designed with a single profile (so one single shape to cover all the crusher explosion chamber), this way the stock of wear parts is reduced and, consequently, warehous costs.

- Side plates

made with heavy-duty 500 HB wear-resistant steel. They are only of three models, with a consequent sharp reduction in stock.

- Double-acting hydraulic cylinders

for heavy-duty service, complete with quick-release couplings.

- Grease lubrication

with grease nipples positioned on the supports, which allow manual lubrication of the bearings and dust-proof labyrinths, from a comfortable and safe operation even when the machine is running.

Thecnical Specifications

Select Model

| Feed gradation |

[ mm ] | 10 - 100 | ||||||

| Capacity |

[ t/h ] | 40 - 60 | ||||||

| Installed power | [ kW ] | 90 - 110 | ||||||

| % Output products Sieve Size |

[ mm ] |

|

||||||

| Impact Bars (Hammers) |

|

|

||||||

| Weight | [ kg ] | 7000 |

| Feed gradation |

[ mm ] | 10 - 100 | ||||||

| Capacity |

[ t/h ] | 60 - 90 | ||||||

| Installed power | [ kW ] | 110 - 132 | ||||||

| % Output products Sieve Size |

[ mm ] |

|

||||||

| Impact Bars (Hammers) |

|

|

||||||

| Weight | [ kg ] | 10000 |

| Feed gradation |

[ mm ] | 10 - 100 | ||||||

| Capacity |

[ t/h ] | 70 - 120 | ||||||

| Installed power | [ kW ] | 132 - 160 | ||||||

| % Output products Sieve Size |

[ mm ] |

|

||||||

| Impact Bars (Hammers) |

|

|

||||||

| Weight | [ kg ] | 12700 |

| Feed gradation |

[ mm ] | 10 - 100 | ||||||

| Capacity |

[ t/h ] | 85 - 150 | ||||||

| Installed power | [ kW ] | 160 - 200 | ||||||

| % Output products Sieve Size |

[ mm ] |

|

||||||

| Impact Bars (Hammers) |

|

|

||||||

| Weight | [ kg ] | 16000 |

Optional

- vibrating distribution feeder designed to receive the material from the feeding belt and distribute it uniformly inside the crushing chamber to produce a homogeneous consumption on the whole width of the hammers (impact bars)

- wear resistant lined feeding hopper for heavy-duty service, suitable to receive the material entering the distributor feeder and conveying it correctly inside the machine

- wear resistant lined discharge hopper for heavy-duty service, equipped with wear plates made of wear resistant steel 500 HB, bolt on style, and wear resistant metal lining on the most used areas.

- hydraulic adjustments of the CSS opening to the impact walls. By means of double-acting hydraulic cylinders, complete with quick coupling and safety valves, it is possible to remotely tune the CSS, from a comfortable and safe position.

- transmission guard made in three sections, bolted together, to allow easy operation. and quick replacement of transmission belts.

- electric motor, transmission belts and motor pulley to be defined based on the application

- hydraulic powerpack complete with high pressure rubber hoses, equipped with quick couplings, to manage the CSS tuning function.

- impact crusher support structure, galvanized, complete with access stairs, inspection walkways and protection

- rotating hoist banner (not included in the supply) to facilitate impact bars (hammers) replacement operations.