AGGREGATES TREATMENT EQUIPMENT

Tertiary Impact crushers

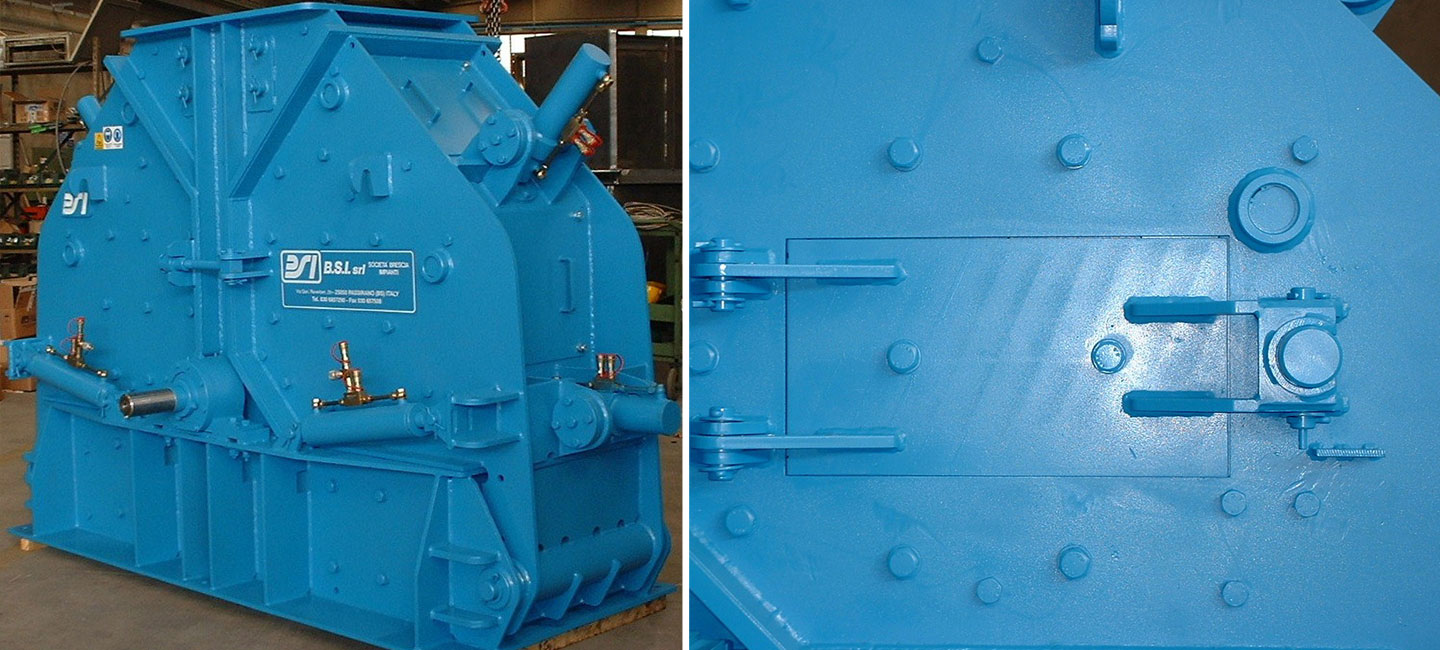

PMC & PFC Series

Tertiary impact reversible crushers PMC and PFC Series, characterized by a wide range of applications, are particularly suitable for the crushing of hard aggregates for the production of sands and fine gravels with Hi-quality form factor, with low content of filler and a compact output gradation.

PFC series ones are well suited to crush small gravels (for example 4-8 mm) resulting from a sand production over-production; this crushing proces produces a great quantity of fine sands (for example 60% of sand passing the 3mm sieve), with very low quantity of filler.

The ease of Use and the reduced maintenance make it the ideal machines to crush fine gravel and stones.

Both series PFC and PMC the used and worn impact bars (hammers on rotor) can be used as a secondary lining to the impact chamber, creating a super long lasting side protection to the crushing volume and reducing the maintenace costs.

Gallery

Main construction specifications

- Bi-directional rotation

the rotor of this crusher is capable in turning both directions, consequently working times are doubled into the respect of a machine with a single direction of rotation.

- Frame and mobile impact surfaces

designed for heavy-duty service, made thick welded metal sheet. They have been calcualted to withstand over-stress in the event of breakage of impact hammers.

- Shaft

heavy-duty, high fatigue resistance steel, supported by wide oversized oscillating roller bearings, which guarantee maximum reliability even in the most demanding applications.

- Rotor

heavy duty construction, made of steel in several sectors, independent of each other, set in phase and fixed each to the shaft by means of binders

- Shaft supports

for heavy-duty service, equipped with grease labyrinth selas for bearing protection.

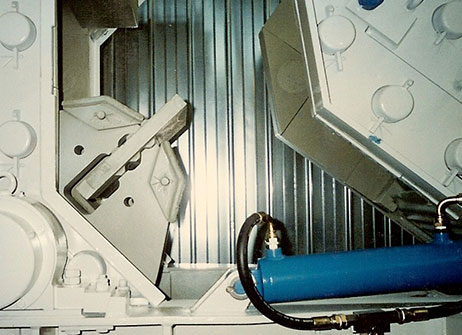

- Hydraulic opening of crusher structure

by the action of hydraulic cylinders feeded through opening speed regulation valves and equipped with a safety valves to prevent accidental closure of the shells during maintenance operations.

- Reversible impact bars (hammers)

for heavy-duty service, slided into the rotor without any locking (to avoid blockage for maintenance). They are made of chrome alloy with a hardness of 62-65 HRC (standard) or Higher depending on the usage and the specific application.

- Impact side armor

for heavy-duty service, in chrome alloy with hardness 56-62 HRC (standard). Designed with a single profile (so one single shape to cover all the crusher explosion chamber), this way the stock of wear parts is reduced and, consequently, warehous costs.

- Side plates

made with heavy-duty 500 HB wear-resistant steel. They are only of three models, with a consequent sharp reduction in stock.

- Double-acting hydraulic cylinders

for heavy-duty service, complete with quick-release couplings.

- Grease lubrication

with grease nipples positioned on the supports, which allow manual lubrication of the bearings and dust-proof labyrinths, from a comfortable and safe operation even when the machine is running.

Thecnical Specifications

Select Model

| Feed gradation |

[ mm ] | 4 - 35 | ||||||

| Capacity | [ t/h ] | 30 - 50 | ||||||

| Installed power | [ kW ] | 110 - 132 | ||||||

| % Output products Sieve Size |

[ mm ] |

|

||||||

| Impact Bars (Hammers) |

|

|

||||||

| Weight | [ kg ] | 6500 |

| Feed gradation |

[ mm ] | 4 - 35 | ||||||

| Capacity | [ t/h ] | 45 - 75 | ||||||

| Installed power | [ kW ] | 110 - 160 | ||||||

| % Output products Sieve Size |

[ mm ] |

|

||||||

| Impact Bars (Hammers) |

|

|

||||||

| Weight | [ kg ] | 8000 |

| Feed gradation |

[ mm ] | 4 - 35 | ||||||

| Capacity | [ t/h ] | 60 - 100 | ||||||

| Installed power | [ kW ] | 132 - 200 | ||||||

| % Output products Sieve Size |

[ mm ] |

|

||||||

| Impact Bars (Hammers) |

|

|

||||||

| Weight | [ kg ] | 9600 |

| Feed gradation |

[ mm ] | 4 - 35 | ||||||

| Capacity | [ t/h ] | 75 - 130 | ||||||

| Installed power | [ kW ] | 160 - 250 | ||||||

| % Output products Sieve Size |

[ mm ] |

|

||||||

| Impact Bars (Hammers) |

|

|

||||||

| Weight | [ kg ] | 11500 |

| Feed gradation |

[ mm ] | 6 - 60 | ||||||

| Capacity | [ t/h ] | 40 - 60 | ||||||

| Installed power | [ kW ] | 110 - 132 | ||||||

| % Output products Sieve Size |

[ mm ] |

|

||||||

| Impact Bars (Hammers) |

|

|

||||||

| Weight | [ kg ] | 6600 |

| Feed gradation |

[ mm ] | 6 - 60 | ||||||

| Capacity | [ t/h ] | 60 - 90 | ||||||

| Installed power | [ kW ] | 110 - 160 | ||||||

| % Output products Sieve Size |

[ mm ] |

|

||||||

| Impact Bars (Hammers) |

|

|

||||||

| Weight | [ kg ] | 8250 |

| Feed gradation |

[ mm ] | 6 - 60 | ||||||

| Capacity | [ t/h ] | 70 - 120 | ||||||

| Installed power | [ kW ] | 132 - 200 | ||||||

| % Output products Sieve Size |

[ mm ] |

|

||||||

| Impact Bars (Hammers) |

|

|

||||||

| Weight | [ kg ] | 10500 |

| Feed gradation |

[ mm ] | 6 - 60 | ||||||

| Capacity | [ t/h ] | 85 - 150 | ||||||

| Installed power | [ kW ] | 160 - 250 | ||||||

| % Output products Sieve Size |

[ mm ] |

|

||||||

| Impact Bars (Hammers) |

|

|

||||||

| Weight | [ kg ] | 12500 |

Optional

- vibrating distribution feeder designed to receive the material from the feeding belt and distribute it uniformly inside the crushing chamber to produce a homogeneous consumption on the whole width of the hammers (impact bars).

- wear resistant lined feeding hopper for heavy-duty service, suitable to receive the material entering the distributor feeder and conveying it correctly inside the machine.

- wear resistant lined discharge hopper for heavy-duty service, equipped with wear plates made of wear resistant steel 500 HB, bolt on style, and wear resistant metal lining on the most used areas.

- wear resistant lined discharge hopper for heavy-duty service, equipped with wear plates made of wear resistant steel 500 HB, bolt on style, and wear resistant metal lining on the most used areas.

- transmission guard made in three sections, bolted together, to allow easy operation. and quick replacement of transmission belts.

- electric motor, transmission belts and motor pulley to be defined based on the application

- hydraulic powerpack complete with high pressure rubber hoses, equipped with quick couplings, to manage the CSS tuning function.

- impact crusher support structure, galvanized, complete with access stairs, inspection walkways and protection.

- rotating hoist banner (not included in the supply) to facilitate impact bars (hammers) replacement operations.