ENGINEERING

"Engineering" and not "design", is the term with which we of the B.S.I. indicate the corporate department that develops the projects of the machines and plants.

Engineering in B.S.I. represents the "added value" to the company's production, especially if compared to the competitor's one. On engineering we spent the majority of our efforts, both economical and organizational, obtaining, along the time, gratifying apreciation by the customers that recognize to our company the highest level in quality and reliability of our systems.

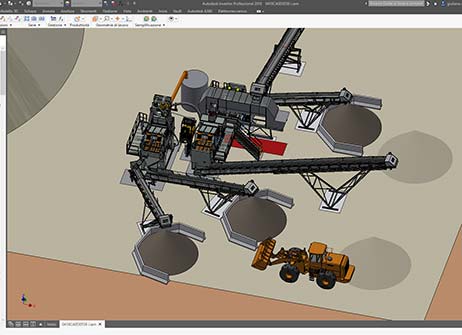

Our team of experts is composed of highly motivated and specialized technicians with a deep knowledge of both mining industry and environmental protection field. By using sophisticated and powerful design tools, part of which have been designed internally to our company, we are able to guarantee a correct and in-depth development of the projects, which are rigorously evaluated, down to the smallest details, with three-dimensional CAD design programs.

Advantages in choosing BSI

OPERATIONS COSTS REDUCTION

INCREASED

PRODUCTIVITY

PRODUCTION PROCESSES EFFICIENCY INCREASE

ENERGY COSTS REDUCTION

BSI Engineering

Engineering in B.S.I. represents the "added value" to the company's production, especially if compared to the competitor's one. On engineering we spent the majority of our efforts, both economical and organizational, obtaining, along the time, gratifying apreciation by the customers that recognize to our company the highest level in quality and reliability of our systems.

Devices and machines department

• finite elements computerized analysis is used to develop the executive projects of machine bodies and all parts subject to greater stress

• dedicated software analyzes the kinematics and the correct sizing of the mechanical parts of the machines, driving to the highest optimization level.

• motion simulation programs allow the symulation of all movements in the machines and to increase their performance by refining the state of the art.

• continuous exchange with end users, "in the field", in order to optimize, for each machine, the ease and simplicity of maintenance operations and the maximum duration of wear components.

Plants department

• use of dedicated algorithms that, based on the flow scheme of the system to be built, the type of material to be treated and the required performance data, determine the load capacity of each individual machine in the plant, allowing the functional parameters to be calibrated to meet the required performances.

• advanced management engineering allows precise planning of production, shipping and assembly phases, in order to fullfil the timing agreed with the customer.

• dedicated software for the management of the installations have been designed by our specialists to be, on request, supplied to complete the system; allowing, from a remote position, the "real time" control of the functionality, to receive notices on the maintenance operations to be carried out, have the instruction and user manual "on line", keeping an archive of all the maintenances performed and the anomalies that occurred, and other data and information useful for the management of production.