ENVIRONMENT PROTECTION PLANT

Soil Washing

Soil Washing is a technique used for the recovery of polluted and contaminated soil generally coming from disused or compromised areas (environmental reclamation). The aim is to maximise the recovery of reusable materials by reducing the amount of waste settled to landfill.

The treatment of soil washing, by the intensive washing of the soil to be treated, removes the pollutants (hydrocarbons and heavy metals in the first place) transferring them to the finerst particles (silts, clays), from the solid phase to the liquid phase and, thus, allow the recovery of the inert fraction with coarser particle size (sands and gravels).

In the liquid phase, contaminants tend to bind to the finer inert fraction (limes and clays). This produces a waste water flow containing suspended solids and pollutants which is sent to treatment of purification and clarification. The clarified water is reused in the washing process by a closed cycle loop, while the sludges obtained in the process of clarification, containing the pollutants, after dehydration, are sent to disposal to landfill.

Feeding Materials

Soil from abandoned industrial areas

Hydrocarbons polluted soil

Roads and railroads foundation aggregates

Various sources polluted soils

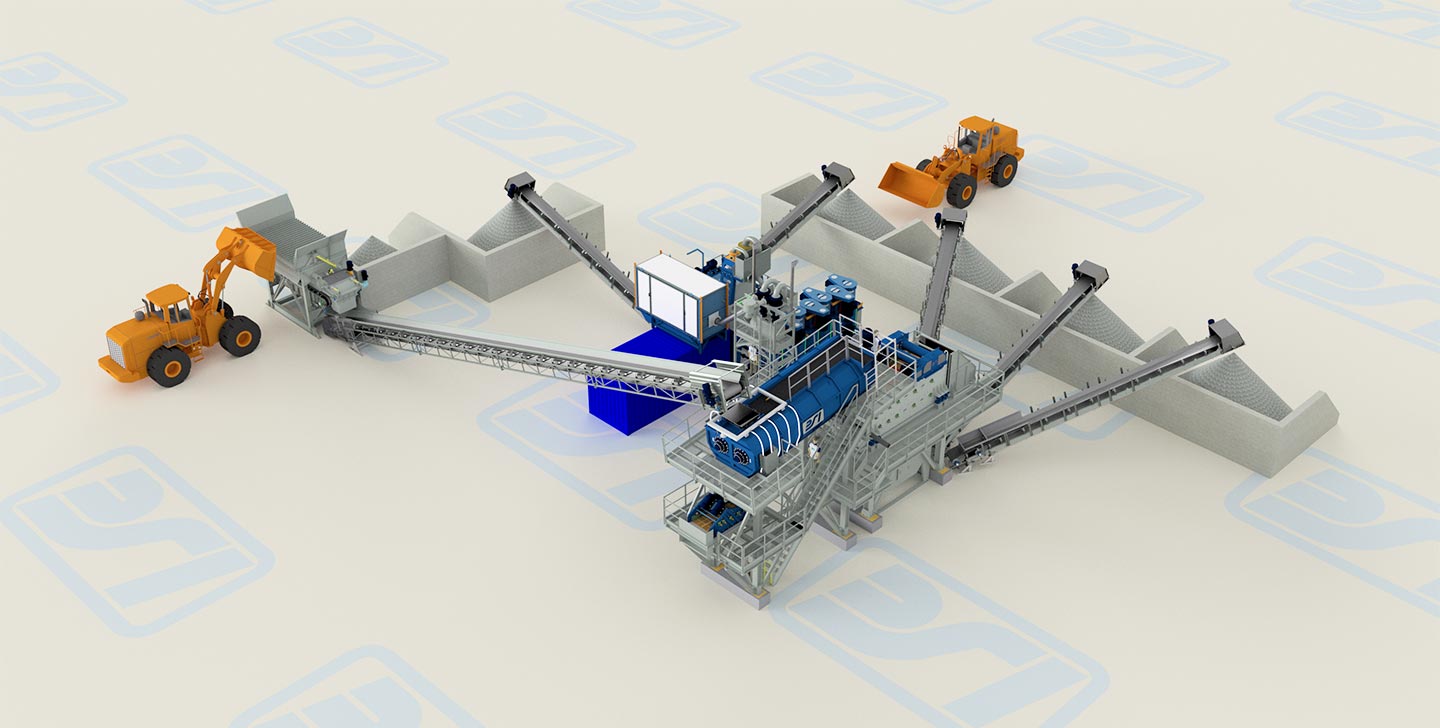

B.S.I.'s Soil Washing Plant

Output materials

SAND:

usable as secondary raw material for civil or industrial application

GRAVEL:

usable as secondary raw material for civil or industrial application

METAL:

sent to the recovery cycle in metallurgical plants

LIGHT ORGANIC:

recyclable in plants for composting or energy recovery

MIXED WASTE:

to be disposed in landfill or used as Secondary Solid Fuel to energy production plats

DEHYDRATED SLUDGES:

sent to landfill or used as compaction substrate for roads and constructions

B.S.I.'s soil washing plant main specs

MODULARITY

The system is designed on the basis of modularity. Each component of the plant, validated and tested on field with excellent performance and reliability results, is chosen and interconnected with the others according to the material to be treated and customer needs.

PRODUCTION POTENTIAL

Solutions for all the capacities required by the market, from the small plant to the high rate production plant.

CUSTOMIZATION

The extensive and in-depth know-how acquired over time with the construction of a large quantity of devices and plants, allows the B. S. I. to develop a plant engineering which is more responsive to the needs of quality, reliability, performance and durability, according to customer's needs.

PROCESS WATER

The process waters used to wash the material, are subject to appropriate physical and chemical clarification and reused in a closed circuit, without any dispersion in the surrounding environment and in full compliance with existing environmental regulations.

CONFORMITY OF PRODUCTS

Contaminants are treated on-site without any pollutant dispersion, while "reusable" materials at the end of the process comply for reuse for civil and industrial applications.

Gallery