AGGREGATES TREATMENT EQUIPMENT

Single toggle Jawcrushers

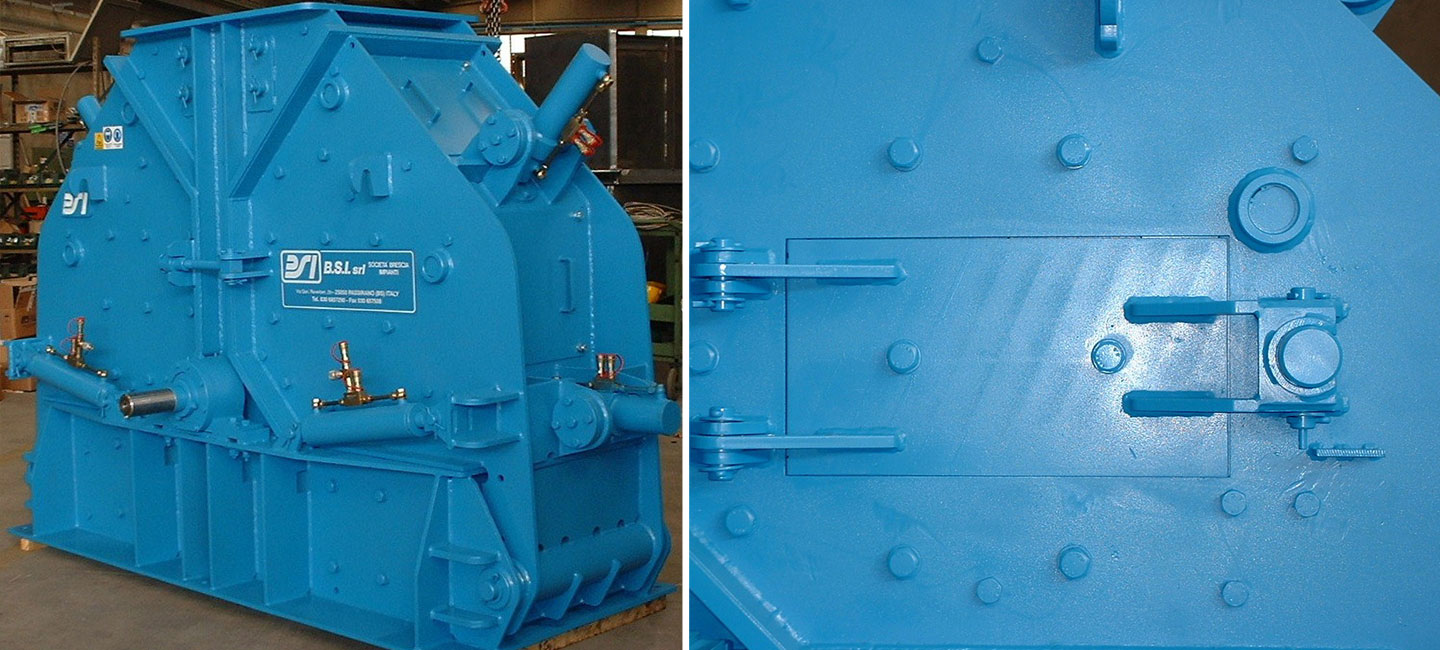

PJC series

Designed for a wide range of applications and high capacity are particularly suitable for crushing hard and abrasive rocks. The correct conformation of the crushing chamber and the cinematic of the B.S.I. crushers, is a guarantee for high performances lastin long in time. The ease of Use and the reduced maintenance required, make it the ideal machines for the primary crushing of stone materials of every type

Gallery

Main construction specifications

- Crushing chamber

carefully designed, with the positioning of the critical section and of the trajectories of the oscillator designed to facilitate the flow of material and, thus, get the maximum production capacity.

- Frame and oscillator

made of deep welded, laser cut, steel sheet. After assembly, they are subjected to a heat stress relief treatment to remove any material stress from the structure.

- Oscillator bearings

housed in special stainless steel sleeves and placed inside the oscillator, instead of directly in the body of the oscillator (most economical choice, adopted by a majority of the builders). This solution ensures, in case of failure of the bearings, a reduced downtime as it is sufficient to replace the respective bushings, and the entire operation is madeon field without the need to rework the oscillator, which would be necessary in case the seats were formed directly in the body of the oscillator, with consequent increases of costs and machine downtime.

- Eccentric shaft

high fatigue resistance steel, supported by wide oversized oscillating roller bearings, which guarantee maximum reliability even in the most demanding applications.

- Fly wheels

made of composite steel and fixed by binders on the eccentric shaft.

- Frame supports

enclosed in special bushes, with grease lubrified labyrinth seals.

- CSS Adjustment

assisted by a hydraulic cylinder attached to the head of the frame, behind the sliding element of the support of the toggle, controlled by a hand pump, equipped with a shut-off valve and is fixed to the housing in an easily accessible position.

- Steel jaws

tooth profiled manganese (standard) or straight profile depending on the application.

- Lateral wedges

built in wear resistant steel 4000 HB, large thickness.

- Toggle

cast iron (for smaller models) or steelwork (for larger models), with interchangeable wear inserts.

- Remote greasing lines

allow the manual (or automatic) lubrication of the bearings with grease, at long intervals of time, from a comfortable and safe position even while the machine is working.

Thecnical Specifications

Select Model

| Load hopper | [ mm ] | 520 x 380 | |

| CSS | [ min-max ] | 30 - 80 | |

| Capacity | [ t/h ] | 15 - 35 | |

| Installed power | [ kW ] | 18.5 | |

| Weight | [ kg ] | 4500 |

| Load hopper | [ mm ] | 620 x 430 | |

| CSS | [ min-max ] | 40 - 80 | |

| Capacity | [ t/h ] | 25 - 50 | |

| Installed power | [ kW ] | 22/30 | |

| Weight | [ kg ] | 7000 |

| Load hopper | [ mm ] | 775 x 550 | |

| CSS | [ min-max ] | 50 - 150 | |

| Capacity | [ t/h ] | 55 - 150 | |

| Installed power | [ kW ] | 37 | |

| Weight | [ kg ] | 10400 |

| Load hopper | [ mm ] | 920 x 600 | |

| CSS | [ min-max ] | 70 - 150 | |

| Capacity | [ t/h ] | 100 - 210 | |

| Installed power | [ kW ] | 75 | |

| Weight | [ kg ] | 13500 |

| Load hopper | [ mm ] | 920 x 750 | |

| CSS | [ min-max ] | 80 - 200 | |

| Capacity | [ t/h ] | 160 - 290 | |

| Installed power | [ kW ] | 75 | |

| Weight | [ kg ] | 18500 |

| Load hopper | [ mm ] | 1130 x 920 | |

| CSS | [ min-max ] | 100 - 250 | |

| Capacity | [ t/h ] | 220 - 380 | |

| Installed power | [ kW ] | 90 | |

| Weight | [ kg ] | 28200 |

| Load hopper | [ mm ] | 1280 x 1070 | |

| CSS | [ min-max ] | 120 - 300 | |

| Capacity | [ t/h ] | 300 - 450 | |

| Installed power | [ kW ] | 110 | |

| Weight | [ kg ] | 45000 |

| Load hopper | [ mm ] | 1530 x 1225 | |

| CSS | [ min-max ] | 150 - 350 | |

| Capacity | [ t/h ] | 350 - 650 | |

| Installed power | [ kW ] | 132/160 | |

| Weight | [ kg ] | 82000 |

Optional

- Automatic lubrication of bearings and labyrinths by means of a special time scheduled grease pump, controlled by a dedicated electric control panel.

- Feed and discharge openings are disigned on Customer requirements.

- Protections, guards, power transmission, are designed and build under customer's specifications amd national specific rules for safety.